6) The KPI trap: Why is ROM production always well below budget?

- hlourens6

- Nov 17, 2025

- 5 min read

This is the sixth article in our series on The KPI Trap.

1. In Article 1, we introduced the trap: how local, functional KPIs create silos and conflict, preventing focus on the actual constraint.

2. In Article 2, we mapped the "vicious cycle" that this creates, in which rational local decisions erode trust and guarantee systemic failure.

3. In Article 3, we showed why teams embrace the solution, "Flow KPIs," because it turns work into a game with clear purpose, mastery, and autonomy.

4. In Article 4, we tackled the "lack of ownership" culture, showing it's a symptom of a system that forces "Debate" (blame) over "Dialogue" (solutions).

5. In Article 5, we examined the history —from Alfred Sloan to modern ERPs —that embedded this flawed "efficiency" logic into our management DNA.

Now, we confront the hard physics.

If you're a mine executive, your environment is defined by pressure. Often you feel like you're firefighting, your calendar is booked for months, and you're constantly pulled into problems your team should have solved. Your mine plan has a "very, very short shelf life".

You see days when the mine sets a production record, and you think, "See? We can do it. Why not every day?" But the average stubbornly settles 20-25% below budget.

The problem isn't your people. The problem is that your mine operations are likely designed according to a "common sense" logic that makes meeting budget impossible.

Let's run a simple thought experiment based on a model we've tested with miners for over 20 years.

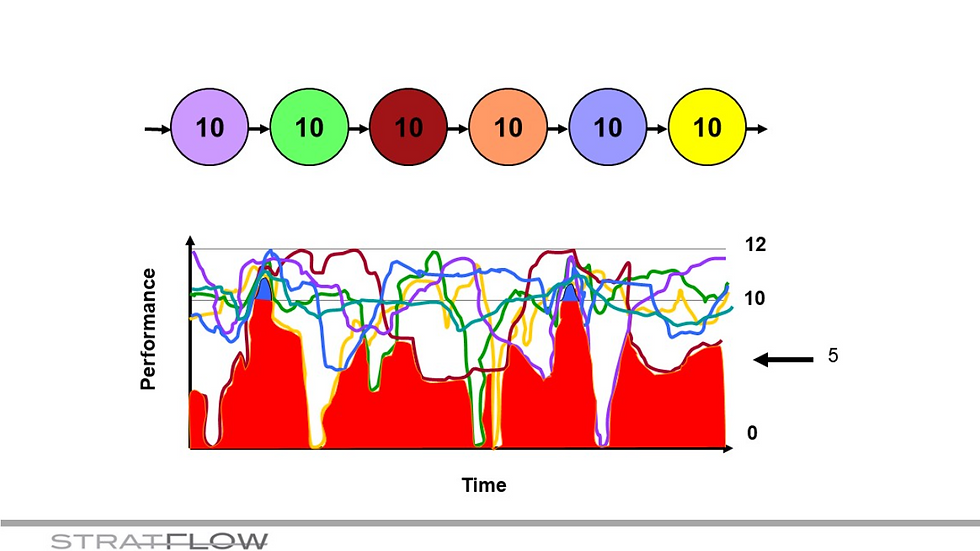

Imagine your mine is a simple chain of six units: Prep, Drill, Blast, Load & Haul, Crush, Beneficiation.

If you could resource every single unit to have an average capacity of 10 tonnes per hour, what would your output be?

10 - 10 - 10 - 10 - 10 - 10 = ?

Most miners, and every traditional budget, say the answer is 10 tonnes per hour. This is the "balanced capacity chain," the peak of efficiency.

This logic is why your mine is failing.

The output of a system such as this isn't 10. Depending on the conditions, it can be as low as five.

Here's why. In the real world, "10 on average" doesn't mean a steady flow. It means:

1. Some hours at 12 tonnes.

2. Some hours at 8 tonnes.

3. Some hours at zero (breakdowns, delays, changeovers).

Now add interdependency: When Unit B breaks down (goes to zero), it starves Unit C and blocks Unit A. At any single moment, the entire system's output is equal to the lowest instantaneous output of any link in the chain.

Because the units are all variable and interdependent, the chance of all six hitting 10 tonnes at the same time is rare (these are your production record days!). The rest of the time, at least one unit is down, and it pulls the entire system down with it.

This can lead to a death spiral:

1. Management builds and resources a balanced 10-tonne average chain.

2. The mine produces 5 tonnes due to variability.

3. Management says, "We're resourcing you for 10 but you only produce 5. We'll cut 'waste' and resource you for 8."

4. The mine produces 4 tonnes.

5. Management cuts resources to 6.

6. The mine produces 3 tonnes, and then it closes.

As Dr. Eliyahu Goldratt stated, "The closer you are to a balanced capacity chain, the closer you are to bankruptcy."

The Physics of Success: 'Inefficiency' Is the Key

The solution is counter-intuitive. To get a reliable 10 tonnes from the system, you must abandon the pursuit of 100% efficiency in every department.

Consider this chain instead:

15 - 16 - 14 - 10 - 13 - 12

When we show clients a real-life chain like this, no one likes it. The efficiency looks terrible. It seems like the 16-tonne unit will be "idle" 37% of the time! Only the bottleneck will run close to 100% efficiency.

But simulations show this design is much closer to an optimal one.

The "10" is the true bottleneck. The "16", "15" and "14" units are protective capacity. (The same is true downstream.) Their job is not to be 100% efficient. Their job is to ensure that, no matter what variability is present, they can recover quickly enough to keep a material buffer in front of the bottleneck filled (and a space buffer after the constraint empty), thus protecting the bottleneck from ever starving. The same is true downstream of the bottleneck. In this way, we decouple the bottleneck from the system's variability and can focus on running it as close to 90% utilisation as possible.

This allows the 10-tonne an hour average bottleneck, when operated at 90% availability, to lift the entire system's output from 5 tonnes per hour to a potential 9+ tonnes—almost doubling output with near zero capital investment.

The Proof: From 2.4m to 3.2m Tonnes

This isn't theory. This is precisely what a longwall mine in New South Wales did.

Averaging 2.4m tonnes per year from 2018-2023, they made a change.

1. They identified the bottleneck: The whole operation was viewed as one system, and the CHPP was identified as the bottleneck.

2. They changed the model: They stopped "pushing" coal from the Longwall and shifted to a "Pull" model based on what the CHPP could handle. This became the "Drumbeat".

3. They used buffers: The ROM stockpile was used as a buffer with clear triggers, giving the system flexibility to absorb delays without stopping the CHPP.

The result? In 2024, they produced 3.2 million tonnes.

As the GM stated, they "unlocked 33% hidden capacity by aligning the parts of the business. No new capex, no new people."

The Human Result: "A Strange Sense of Calm"

This shift in physics transforms the human environment. When the system is stable, the chaos disappears.

The Head of Operations at the mine described coming to work and "feeling a strange sense of calm... wondering if this is what his role was 'meant' to feel like".

Safety improves dramatically. Why? Because you eliminate the "spot fires" and rushed, reactive decisions, which regulators note are a primary cause of injuries.

This is the "virtuous cycle" (Article 2) in action. It's the "Dialogue" (Article 4) that replaces "Debate." It's what makes work feel like "golf" (Article 3), where crews are "engaged and aligned".

As one manager said, "There isn't a single person I speak to that hasn't asked why we didn't do this sooner".

Your Choice: Manage Costs or Manage Flow?

As an executive, you are at a crossroads.

You can continue to manage by the old paradigm—chasing "efficiency," balancing capacity, and demanding accountability for siloed KPIs. This will keep you trapped in the "vicious cycle," fighting your own people and wondering why productivity is stagnant.

Or, you can accept the physics.

You can shift your focus from optimising the parts to optimising the whole. This involves:

1. A Focused Methodology: Using Theory of Constraints (TOC) to find the one leverage point that matters.

2. Adding the missing link to your operations: Implementing a daily Flow Room—a 30-minute, forward-looking meeting that aligns everyone on protecting the constraint.

3. A Different Kind of Partner: Engaging a team that specialises in this "keyhole surgery" approach, delivering rapid results (weeks, not months) and sharing the risk by tying fees to your achieved outcomes.

Your mine's hidden 30% capacity is not in new capex. It's locked up in a flawed management model. The choice is whether you're ready to stop fighting physics and start working with it.

Comments