10) The KPI Trap – The Simulation Team Did Not Fail, Operating Beliefs Did

- Dec 19, 2025

- 6 min read

In my previous article, I made a point that stings a bit: You can feed what you think are P50 assumptions into a stochastic engine… and discover that your “P50” completion date behaves more like P02 in the real world. The tool hasn’t failed — it’s calmly telling you the system you’re planning is physically incapable of delivering the promise with any reasonable confidence.

That’s why some executives feel burned by “better planning” investments: they improved the modelling, but didn’t change the mine’s underlying flow design — so the tools became highly accurate messengers of bad news.

And as I said there, you can’t spreadsheet your way out of a brittle system.

Now I want to follow up with the next problem. Because many mines bring in excellent simulation teams. They identify the true constraint. They recommend the right buffers, protective capacity, and control logic. The business case often looks great. And then… nothing changes, or six months later, everything drifts back.

Why Simulation and TOC So Often Stall at Exactly This Point

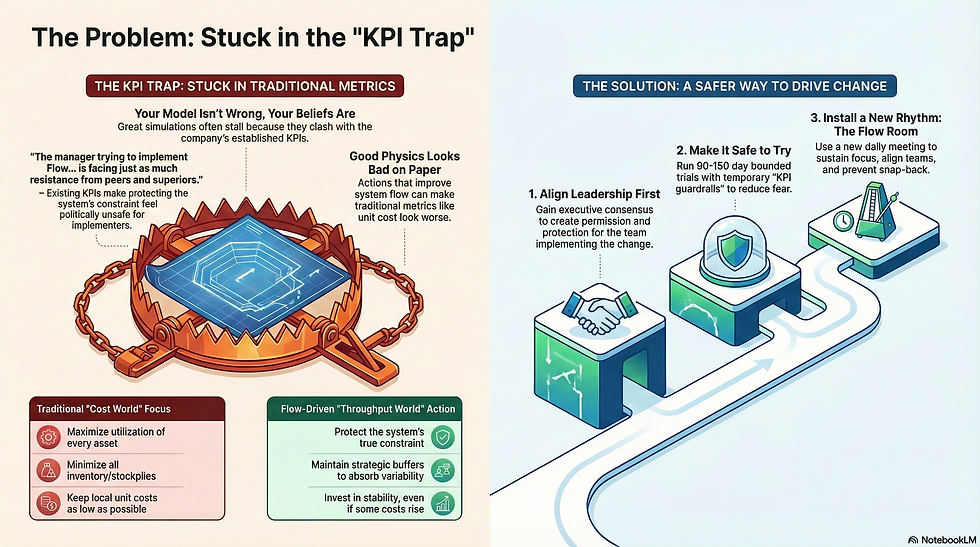

If you’ve ever had a simulation or TOC project recommend the “counterintuitive but correct” moves — more buffer here, more slack there, protective capacity on non-constraints — you may have seen the same pattern:

The model is convincing.

The payback is short.

But operations and finance push back because (on paper):

Unit cost/tonne rises.

Inventory / working capital looks worse.

ROCE / ROI may dip before the uplift shows

And there’s no KPI for “stability of the constraint”

So even a proposal that could unlock 20–40% more output using existing assets can die quietly in the KPI trap.

This is the key point: You don’t have a modelling problem. You have a change architecture + KPI problem.

But beneath that lies something deeper: outdated operating beliefs. These are the mental models that shape how everyone—from the COO to the frontline crew—interprets what "success" looks like. Traditional beliefs prioritise local efficiency, balanced utilisation, and immediate cost control. Flow challenges these by emphasising system-wide throughput, deliberate unbalancing, and investing in stability over short-term optics. Without addressing these mental models head-on, even the best simulations gather dust.

The Implementing Manager Gets Hit from Both Sides

Here’s what mine executives often underestimate: the manager trying to implement Flow isn’t only dealing with frontline resistance. They’re often facing just as much resistance from peers and superiors — because the current KPI environment makes “protecting the constraint” feel politically unsafe. And it’s not because people are irrational. It’s because Flow asks leaders to do things that look wrong in a traditional KPI pack — like this longwall example: For years, plans and KPIs drove one mantra: keep the longwall cutting hours high. But the true economic constraint was the CHPP. The ROM stockpile repeatedly ran empty, so the plant couldn’t run at capacity. When leadership flipped the logic to protect the plant (by managing a target ROM band), system output lifted ~33% — even though it “looked terrible” on paper (dozer hours, rehandle, longwall stopping early).

That’s the conflict: good physics looks bad in Cost World. Shifting to Flow requires confronting these entrenched beliefs. Executives must recognise that what feels "right" under old models—maximising every asset's utilisation—actually amplifies variability and erodes throughput. Assuring implementers that this shift is backed by data and real-world results is crucial, but so is demonstrating early wins to build confidence across levels.

What StratFlow Has Learned After 20 Years: Facts Don’t Change Mines — Experiences and Understanding Do

StratFlow exists to close the gap between “simulation truth” and “daily behaviour”. Not with more PowerPoints — but with an approach that reduces fear, reduces political risk, and installs a management rhythm that prevents snap-back.

The core challenge isn't technical; it's human. Mental models like "efficiency means no idle time" or "balance everything to minimise costs" are deeply ingrained. To shift them, you need shared experiences that prove the new way works—not just for the bottom line, but for daily operations. This means involving managers and workers early, letting them see how Flow reduces chaos and empowers their decisions.

Align the Senior Team First (So the Implementing Manager Isn’t Exposed) A CHPP Manager put it bluntly: success required a catalyst and acceptance at the senior level that the current operating philosophy wasn’t going to improve the mine’s outlook — then StratFlow helped fill the missing ingredients like the Flow Room, building ownership and momentum with each win.

That’s why we start with an executive alignment session: to create permission and protection for the trial. This step addresses mental models at the top. Executives must internalise that Flow isn't a risk—it's a necessity for resilience. By aligning here first, you assure mid-level managers that they're not going it alone and show workers unified leadership, reducing scepticism.

Translate Simulation into a Story Leaders Can Repeat (Not a Report People Forget) Executives don’t need more data. They need a simple narrative linking Flow + buffers + constraint stability to tonnes, cost, risk, and safety. Because if your supervisors can’t explain why “protective capacity” is the cheapest insurance you can buy, the organisation will default under pressure.

Crafting this narrative helps rewire mental models. It's not about selling change; it's about showing why the old beliefs no longer serve in variable, interdependent systems. When managers and workers can retell this story, buy-in grows organically.

Make It Safe to Try: Bounded Trials + Temporary KPI Guardrails. This is where emotion beats logic. That same mine described “some level of angst” about trying something so different — but once critics were reassured “we could turn it off and go back overnight”, a rollout strategy was built, training and shadowing done, and then they “ripped off the Band-Aid.”

Trials like this assure implementers that failure won't define their careers. They also provide hands-on experiences that challenge old beliefs, showing workers how Flow leads to calmer shifts and managers how it delivers sustainable results. This shared proof builds collective commitment.

Use the Flow Room to Sustain (and Accelerate) the Change. This is the part most simulation projects don’t leave behind: a new daily operating rhythm. The Flow Room keeps the signal clear, aligns reporting/incentives/KPIs to a common goal, and keeps people focused on flow. It also provides earlier warning (e.g., projected buffer levels), allowing teams to plan calmly rather than react in panic.

And the emotional outcome is real: Workers said it was the best system they’d seen in the mine’s history — “everyone’s more relaxed, and we’re working together.”

Their Head of Operations described a “strange sense of calm” replacing firefighting—and wondered if that’s what the role was meant to feel like.

The Flow Room reinforces new mental models daily. It's where managers and workers alike experience the benefits—less stress, clearer priorities, better collaboration—cementing the shift.

For Mine Executives: A Safer Way to Do Something Different

If you have a burning desire to do something different — but you’re worried it will have negative effects, or that your managers will resist — start here:

Name the constraint and align the senior team on what “winning” means (throughput +

stability, not local utilisation).

Run a 90-150-day bounded Flow trial with temporary KPI guardrails so nobody gets punished for protecting the constraint.

Install the Flow Room so the new behaviour survives the first crisis — and becomes the mine’s new normal.

Once these Flow-aligned KPIs and rhythms are in place, the underlying physics of the mine changes: protective capacity and properly sized buffers absorb normal variability, the system stops being brittle, and your weekly and monthly plans finally gain real shelf life. What used to break by Wednesday now holds as a reliable steering tool — delivering the stability that stochastic models promised but could never achieve on their own.

Because better maths cannot overcome bad physics. And better physics doesn’t stick without better change architecture.

The real imperative isn't adopting Flow for its own sake—it's recognising that clinging to outdated mental models keeps mines trapped in cycles of frustration and underperformance. When executives lead the shift in beliefs, ensuring buy-in from managers and workers through alignment, stories, safe trials, and sustained rhythms, the path to higher throughput and calmer operations opens. It's not about forcing change; it's about enabling a system where everyone sees the need and benefits from doing things differently.

Comments